ATOP Ceramic Tiles Rainbow Color Coating PVD Vacuum Coating Machine

Main Feature

1. Rapid deposition rate and small temperature rise can inhibit the phenomenon of fire and target

poisoning.

2. The high energy emitted by sputtering has significantly enhanced the membrane density and adhesion.

3. The touch screen +PLC can achieve full automatic control, automatic/manual switching.

4. Large volume, large loading capacity and high production efficiency.

5. The workpiece frame adopts the public rotation structure, which can set the automatic positive and

backward rotation, and the product is even good.

6. Reasonable configuration, quick pumping rate, low noise, low energy consumption.

7. The film layer deposited by this equipment can meet customer requirements in terms of density,

uniformity, purity and hardness.

Working Principle

Vacuum magnetron sputtering coating machine working principle:the so-called "splash", the electrons in

an electric field under the action of accelerating the process of flying to the substrate with argon atom

collision, ionization out large amounts of argon ions and electrons.The electron flies toward the substrate,

the argon ion speeds up the target material under the action of the electric field, sputtering out a large

number of target atom, and the neutral target atom (or molecule) is deposited on the substrate to form the

film.Secondary electron in accelerating to fly to the substrate by magnetic field in the process of lorentz

magnetic force, the influence of confined area near the target surface plasma, the plasma density in the

area is very high, secondary electron under the action of magnetic field around the target surface is

circular motion, the electron motion path is very long, constantly in the process of movement of the impact

ionization out large amounts of argon ion bombardment of target, after many times of collision of the

electron energy gradually reduce, cast off the yoke of the magnetic field lines, away from the target

material, the final deposition on the substrate.

Equipment Configuration

Vacuum coating machine is the most environmental and friendly surface treatment machine without waste

and harmful gas and liquid.

The specific configuration of coating machine can be designed according to process requirements of

coating products.

Vacuum coating machine make the metal deposition on surface of the product,make the it colorful,

beautiful,function Strong adhesion , good compactness, well repeatability and consistence of color.

Structure type:Vertical type or horizontal type

Chamber type:single door or double doors

Product Name

|

ATOP Ceramic Tiles Rainbow Color Coating PVD Vacuum Coating Machine

|

Vacuum Chamber Size

|

Decide according to the substrate size and output |

| Substrate |

Hardware,glass crafts,ceramic crafts,such us watches,mobile phone metal

shell,sanitary ware,mould,electronic products,crystal glass, glasses, cutlery, knives

and so on

|

Coating Film

|

High-grade decorative coating. |

| Coating Color |

Gold, rose gold,coffee,brown,bronze,blue,black,white,gray etc.

|

| Applications |

Hardware,glass crafts,ceramic crafts such us watches,mobile phone metal

shell,sanitary ware,mould,electronic products,crystal glass, glasses, cutlery,knives

and so on.

|

| Structure |

Vertical type ; horizontal type ; single door type ; double-door type.

|

| Coating Material |

Stainless steel, aluminum, titanium, tungsten and other metal films may

be manufactured as coated TIN, TIC, TICN, TIALN, CRN, CU, AU, diamond film

(DLC), decorative film metal, film and non-metallic composite coating film and its

compounds film.

|

| Features |

High pumping speed, high efficiency, energy saving, full automatic process

controller can be simple, reliable, beautiful.

|

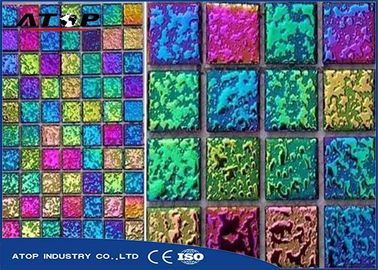

Coating Samples

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!